Machine gun cap (reinforced concrete firing point)

- Головна >

- Machine gun cap (reinforced concrete firing point)

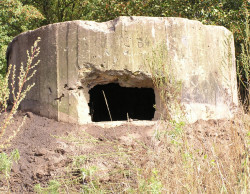

A machine-gun hood is a standard-sized field fortification that can be quickly erected. It could be solid or consist of separate parts. It was made of metal, multilayered metal-sand-metal, or reinforced concrete. Metal caps were also called BOTs (Russian: бронированнаяогневаяточка), and reinforced concrete caps were called ZHBOTs (Russian: железобетоннаяогневаяточка). The construction of a pillbox is an expensive and time-consuming task. The construction of a simple MS-type pillbox for one machine gun (for example, pillbox No. 301 (KiUR)) required digging a pit of 105 m³, a volume of concrete of 65 m³, and 2,409 man-hours of labor.

It is impossible to shelter every machine gunner in a pillbox. Maneuver warfare may require the construction of fortifications in places where the military would not have thought of it before the war (for example, around Moscow).

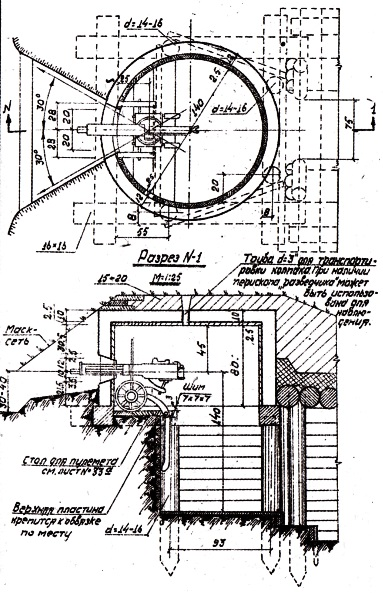

The solution to these problems was the machine gun cap. It could be manufactured in the rear, and in series. It was brought to the front line and installed quickly. A typical reinforced concrete cap was developed in the design bureau of the Main Military Engineering Directorate by military engineers S.V. Barsukov, P.K. Buznik and L.N. Nikolsky. Subsequently, it was included in the album of standard designs of the GVU and in the manual for engineering troops on field fortification. Hoods of other designs were also used.

A typical reinforced concrete cap had a diameter of 1700mm, a height of 900mm and a wall thickness of 130mm. The height of the embrasure was 370-400mm and the width was 400-500mm. The volume of reinforced concrete was 0.8 m³. Weight from 1300 to 2000 kg, depending on the concrete grade. The required volume of the pit is 10 m³. Labor intensity of production is 60 man-hours, installation time with a crane is 0.5 hours.

The roof of the cap had a hole for a trench periscope. Some caps had not only an embrasure but also an exit. Reinforcement loops came out as mounting loops. The internal formwork was connected to the reinforcement and remained in the finished product as an anti-chip.

The metal cap with the same dimensions and wall thickness of 35-40 mm weighed up to 2000 kg.

The multilayer cap consisted of two metal caps with a wall thickness of 6-8 mm, between which a 150 mm sand layer was driven. It weighed up to 2000 kg.

At the position, the cap was installed on a base. As a rule, it was a log house, but a concrete "cup holder" was also used. A table for the machine gun was installed in the log house. The hood itself was covered with earth, as were the Barbet and TAUT machine gun nests. In all of these structures, the thickness of the concrete wall is insufficient to reliably protect the garrison even from shrapnel (400 mm according to the standards of those years).

They were used en masse, literally by the thousands by the Red Army and to a limited extent by the Wehrmacht.

During the tests, a solid metal cap showed the best results, while a reinforced concrete one showed the worst. It could not hold a line of automatic weapons, when all the bullets hit more or less the same spot.